Ready to dive deep into mobile homes and their HVAC systems? You’re in the right place. We’re discussing flex ductwork today – an unsung hero in your mobile home’s comfort. It may sound technical, but it’s crucial. The size of your flex ductwork impacts everything from your comfort to the efficiency of your heating and cooling system. So, buckle up! We’re about to unravel the mystery of standard flex ductwork sizes in mobile homes. Let’s get started!

What is Flex Ductwork?

What exactly is it? I’m glad you asked. Think about flex ductwork like the blood vessels of your HVAC system. Just like your arteries and veins carry blood throughout your body, flex ductwork transports warm or cool air from your HVAC system to each room in your mobile home.

The ‘flex’ part is short for flexible. Unlike traditional rigid ductwork made from metal, flex ductwork is constructed with a springy wire coil covered by a layer of flexible plastic and then insulated and enveloped by a foil-like outer shell. This design gives it the superpower of flexibility! It can twist, turn, and wiggle around obstacles that would block more rigid types of ductwork.

What makes flex ductwork a favorite among HVAC pros, especially for mobile homes, is its ability to reach the hard-to-get spots. It’s like a contortionist, bending and flexing to fit into small, awkward spaces, bringing that sweet, conditioned air to every corner of your home.

Getting the size right is crucial. Too big, and your system will waste energy. Too small, and it won’t be able to transport enough air to keep your home comfortable. We’ll investigate flex ductwork sizes in the following sections, so stay tuned!

Sizes of Flex Ductwork in Mobile Homes

Okay, now that we’ve covered flex ductwork and why it’s essential, let’s dive into sizes. In the flex ductwork world, size isn’t just about fitting into your mobile home’s space. It’s about ensuring your HVAC system can breathe easily and work efficiently. So, what sizes are we talking about? Flex ductwork comes in several standard sizes, typically 4 to 14 inches in diameter. Let’s break down the most commonly used sizes in mobile homes.

- 4-Inch Flex Duct

This little guy is perfect for smaller spaces, like tiny homes or compact sections of a larger mobile home. It’s petite but can pack a punch in the right situation.

- 6-Inch Flex Duct

The 6-inch duct is a step up and is excellent for individual room heating or cooling. It’s often used to connect the main ductwork to individual room vents.

- 8-Inch Flex Duct

When you need more airflow, the 8-inch size steps into the game. It’s a good size for larger rooms or spaces needing more heating or cooling love.

- 10-Inch to 14-Inch Flex Duc

Now, we’re moving into the realm of main ductwork for many mobile homes. These sizes are designed to handle a larger volume of air, connecting to your HVAC system and branching off to the smaller ducts that serve individual rooms.

Remember, it’s not a one-size-fits-all situation. The best size for your mobile home depends on factors like your total square footage, your HVAC system’s capacity, and how well-insulated your home is. It’s a delicate balancing act to ensure optimal comfort and efficiency.

Effects of Improper Flex Ductwork Sizing

First, if your ductwork is too small, it’s like trying to push a river through a straw. The airflow from your HVAC system can get choked off, leading to less heated or cooled air reaching your rooms. It also means your HVAC system has to work overtime, like a marathon runner who can’t slow down. The result? Higher energy bills and a system that wears out sooner than it should.

And let’s not forget the most essential part – rooms that feel like a sauna in summer or a freezer in winter. Not fun, right?

On the flip side, if your ductwork is too big, it’s like a river flowing into a lake. The air can spread out and lose speed, so it might not be pushed into your rooms effectively. It’s a bit like having a sports car with no gas pedal. Sure, it has the power to speed, but it’s going nowhere fast without control. Again, the result is higher energy bills and an HVAC system working harder than needed.

In a nutshell, incorrect flex ductwork sizing can lead to inefficient heating and cooling, increased energy costs, and reduced lifespan of your HVAC system. Plus, it can leave you shivering or sweating; nobody wants that!

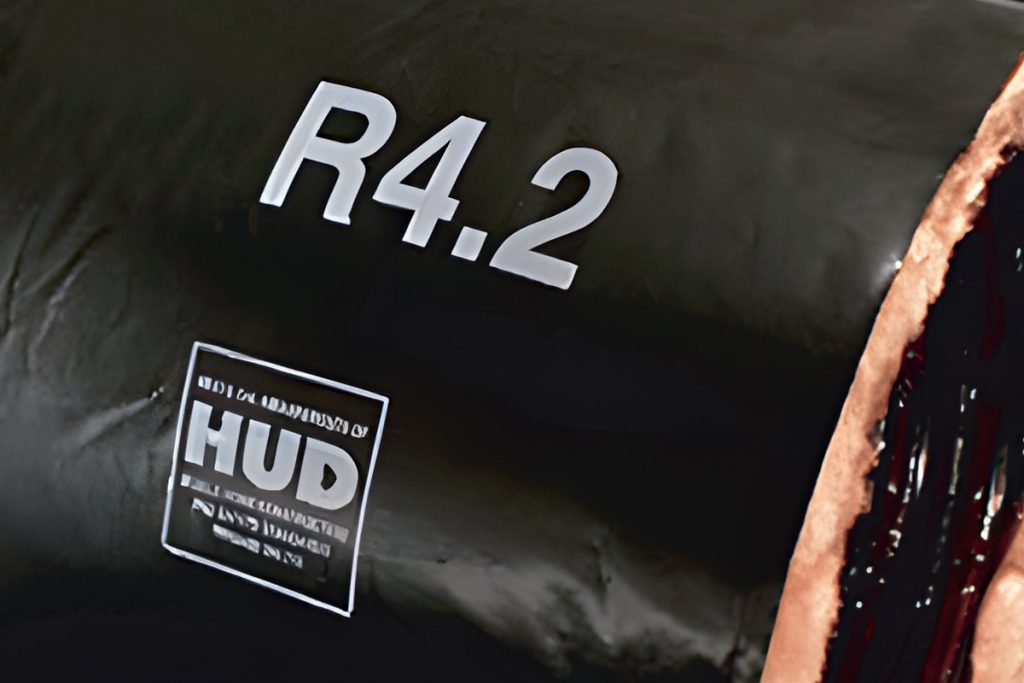

Mobile Home Flex Ductwork R-Rating

In the world of insulation, R-rating is king. It’s a measure of how well a material resists the heat flow. In other words, it tells you how good the material is at keeping heat where you want it – inside your home when it’s cold outside and outside your home when it’s hot out there.

Now, how does it apply to flex ductwork? The R-rating in this context measures how well the insulation around your flex ductwork can prevent the air flowing through it from losing its warmth in winter or coolness in summer. Pretty important, right?

Typically, flex ducts come with insulation that ranges from R-4 to R-8. The higher the R-value, the better the insulation.

- R-4 Insulation: This is your basic level of insulation. It’s okay in milder climates, but you might want to level up if you’re dealing with harsh winters or scorching summers.

- R-6 Insulation: Here, we’ve got a bit more insulation power. It is the middle-of-the-road option and works well in a variety of climates.

- R-8 Insulation: This is the heavyweight champ of ductwork insulation. It’s perfect for extreme climates or anyone wanting to maximize energy efficiency and minimize heat or coolness loss.

A higher R-rating means better insulation, so your HVAC system doesn’t have to work as hard to keep your home comfortable. And a happy HVAC system means lower energy bills and a happy you!

How Do I Know What Size Flex Ducts I Need?

How do you figure out what size flex ducts your mobile home needs? It might sound complex but don’t worry. I’ve got you covered!

1. Compact Mobile Home

Suppose you have a single wide mobile home, around 500 square feet. It’s cozy, and your rooms are close together. In this case, your HVAC system probably isn’t massive, so you could use smaller ductwork sizes, like 4 to 6 inches in diameter, to effectively deliver air throughout your home.

2. Mid-sized Mobile Home

Let’s scale to a mid-sized mobile home, perhaps around 1,000 square feet. You’ve got more space and more rooms to heat or cool. Your HVAC system is probably a bit more robust too. You might need slightly larger ductwork, say 8 to 10 inches, to handle the increased air volume and reach every room effectively.

3. Large Mobile Home

Finally, imagine a double-wide mobile home, around 1,500 square feet or more. The rooms might be spread out, and your HVAC system has to work harder to heat and cool all that space. In this scenario, you’d likely need larger flex ductwork. Perhaps in the 12 to 14-inch range to efficiently distribute air throughout your home.

These are just examples; many factors can influence the right ductwork size for your specific situation. That’s why it’s always a good idea to hire a professional HVAC technician when you’re unsure. They can assess your home and HVAC system and help you choose the optimal ductwork size.

Conclusion

Flex ductwork sizing in mobile homes it’s all about balance. Your ductwork needs to be large enough to carry enough air to keep your home comfortable. But not so large that your HVAC system can’t keep up. It’s like Goldilocks and the Three Bears. You want to find the ductwork size that’s “just right” for your mobile home!